The term “lean” has recently gained more and more traction in the discussion of construction methods. With an increasing number of people talking about it, how do we take it from a construction buzzword to a fundamental practice in everything we do?

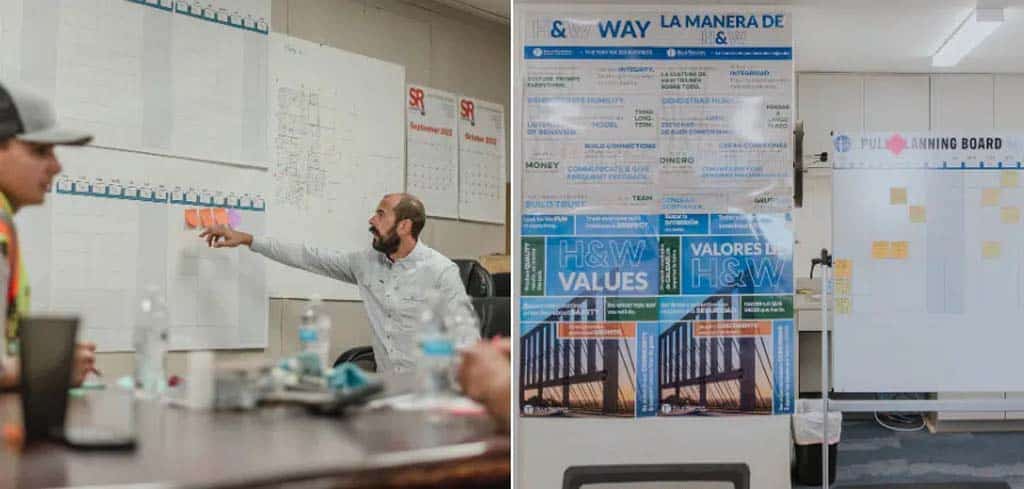

Implementing lean on a jobsite starts during preconstruction and pre-awards. Incorporating lean language into the bidding instructions and the general inclusions of the contract and emphasizing our trade partners’ commitment to lean is crucial. H&W establishes the lean culture and expectations from day one. Our project team also serves as lean champions throughout the project, consistently reinforcing expectations through leading by example.

Danny describes lean as a beneficial tool that promotes improved communication, “When utilizing the lean tools we currently have the project as a whole is coordinated better largely due to the level of communication that starts to happen. And, by default, with better coordination and communication, you see that project being managed at a substantially different level, which results in higher safety scores and a likely acceleration of the project schedule.”

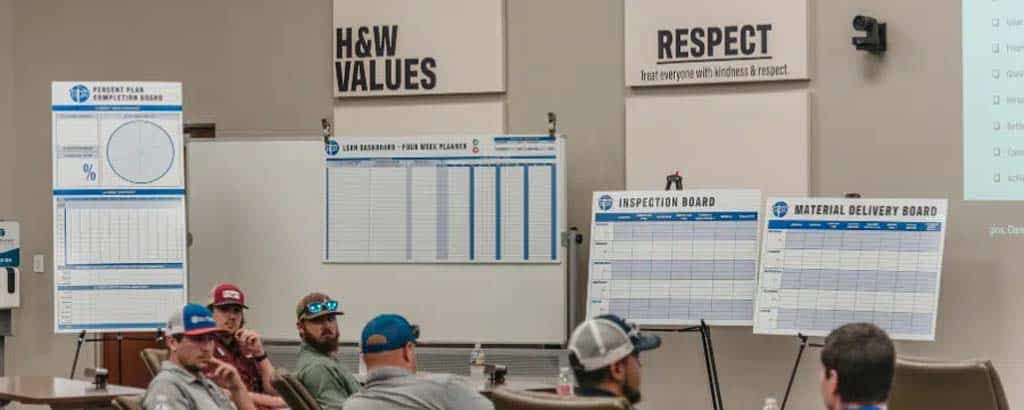

There are certain lean tools that can especially set up a project for success. One is pull planning, which is a collaborative technique that coordinates the schedule/milestones and identifies activities to save time, resources, and money. Often displayed in the job trailer or out on the jobsite, a pull planning board allows for collaboration between the project team, design team, and owner. Danny adds, “If pull planning is done early, even prior to mobilizing the project, the team can be extremely proactive, identify constraints, and offer solutions very early.” Another lean tool we use is the daily huddle. This is a quick meeting each day where the team asks each trade partner a list of questions pertaining to the day’s work and references other tools, like the delivery board, inspection board, weekly work plan, constraint management board, and the parking lot.

Lean methodologies enhance H&W’s Core Four Foundations of Construction: Safety, Quality, Schedule, and Cost. Through the implementation of lean processes, project communication and coordination are significantly improved, which elevates project quality and safety. With strategic allocation of time and schedule, there is no need for rushed completion and “fire drills,” preserving the integrity of our projects. We believe by incorporating lean into all that we do not only improves efficiency, but empowers our people to do their best work. That’s why at H&W we’re building lean, together.