Working side-by-side with our client’s operations team, our first step is an in-depth analysis of their process flows, equipment, environmental requirements and productivity measures.

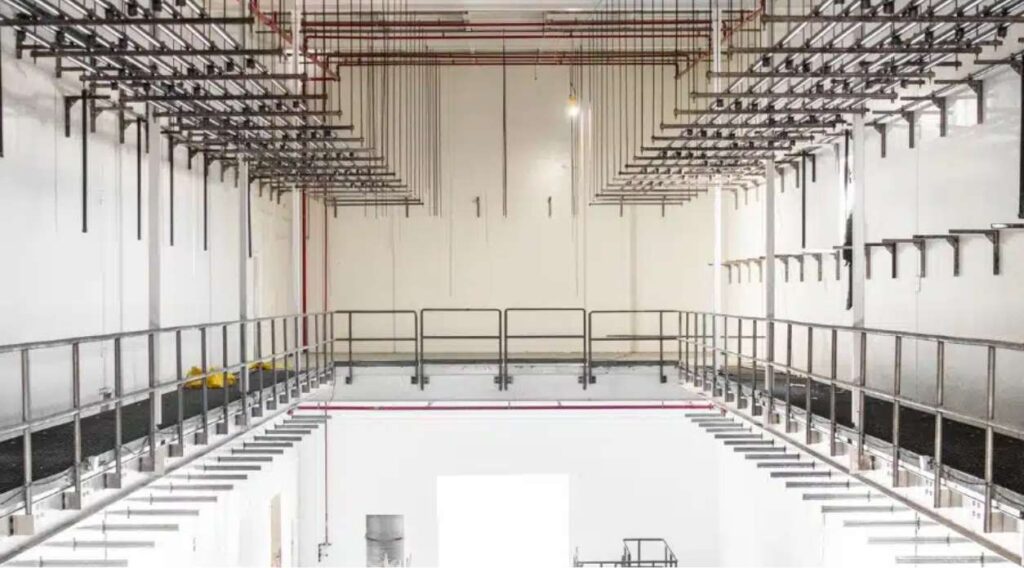

We start by breaking down the facility into process areas and then dive further into process equipment. Whether equipment will be relocated from another facility or ordered directly from the fabricator, we assist our clients with documenting every possible condition including perimeter wall access openings, spatial requirements and clearances, foundations, vibration criteria, environmental requirements, utility connections, heat loads, controls, and more. We frequently assist with the purchasing, delivery, scheduling, logistics, and final installation of each piece as well.

Through a complete review of both past and future procedures, we will develop an in-depth understanding of your process requirements. This Process-Driven approach makes us better designers and builders while also making solutions more efficient.

“The professionalism from each individual involved on this project has exceeded any expectation or experience I have had on any project. Preconstruction, design, and estimating continually exceed expectations, and I want you to know how thankful we are. Congratulations to everyone, and as always, exceptional efforts lead to exceptional results from the entire team.”

— Confidential Manufacturing Client